Referenzen & Projekte

When technology makes an impact – right here

Behind the scenes – genuine impressions

Where our solutions run – and not just in demo mode

Where our solutions work

One process. Ten solutions. Countless applications.

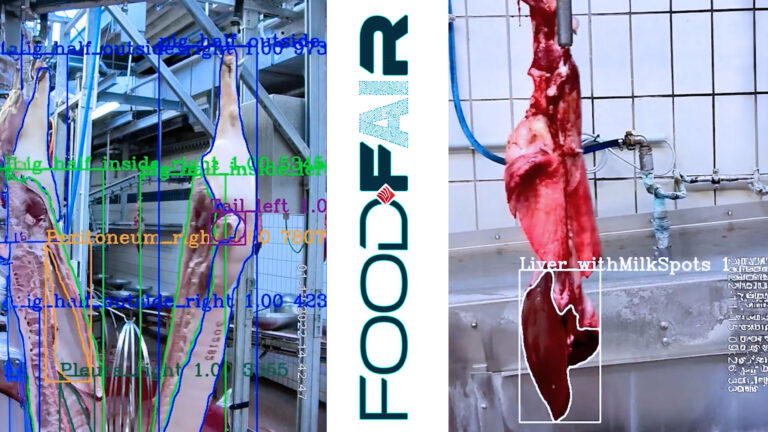

Beef carcass classification, product recognition

RFID, slaughter number recognition

Photo documentation, organ findings

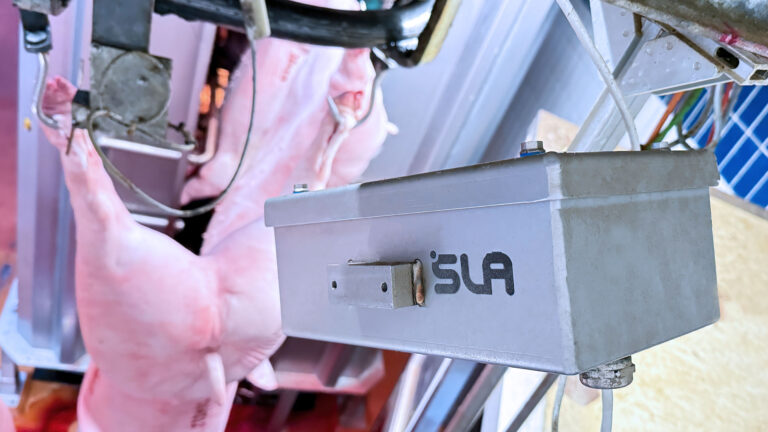

Product recognition, gender recognition

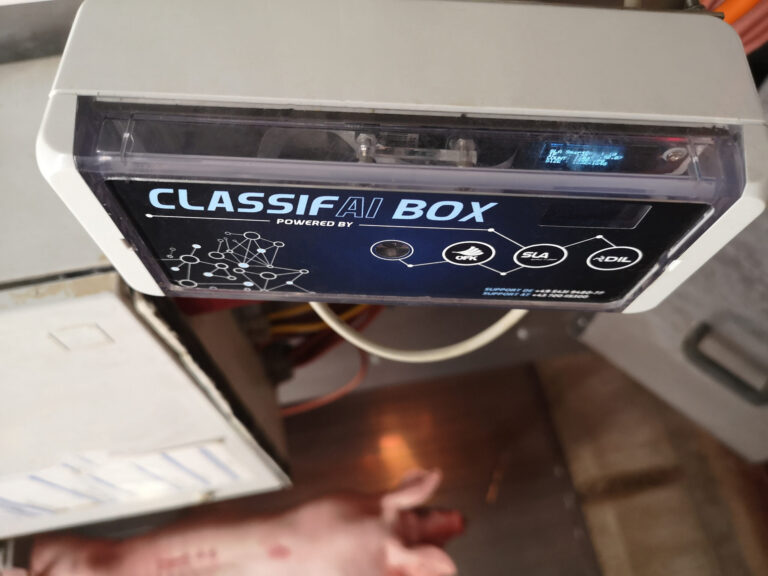

ClassifaiBox + combined AI modules

Our solutions are designed not to intrude on processes, but to blend seamlessly into them. Right where they make the biggest difference.

Our success stories

Projects with impact. Partners with high standards

What our solutions achieve in everyday life cannot be summarized in bullet points. You have to see them in motion, in real lines, with real people. Our success stories tell you all about it—about companies that are boldly rethinking processes, about the courage to not just test AI, but to use it. And about the end result: less effort, more security, and real relief. Here is one of these projects. More will follow shortly.

AI solution in cutting operations

Product recognition in live operation

AI solution in cattle slaughterhouse

Beef carcass classification in live operations

AI solution in pig slaughterhouse

Gender- and slaughter number recognition in live operation

Ready to take the first step?

Whether you have a specific project, an idea in mind, or simply want to ask, “Can we do this?” We listen, think along with you, and contribute our technical and professional expertise. Because every good project begins with a conversation. Perhaps that is precisely what makes the difference today.