Our AI solutions

Slaughter number recognition

Automatically recognized – reliably linked, traceably documented.

Your Challenge Challenge Challenge

If the number is not readable, there is no connection.

Slaughter numbers are the central anchor for traceability, classification, diagnosis, and animal welfare indicators. However, they are often read manually and recorded by hand—in an environment that is wet, confusing, and hectic. Smudged numbers, missing entries, and manual transcription errors jeopardize the linking of animal data to the slaughter process.

Our Solution Solution Solution

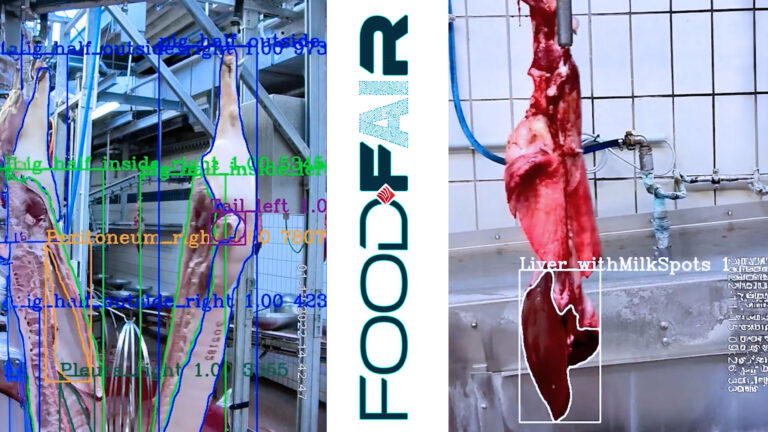

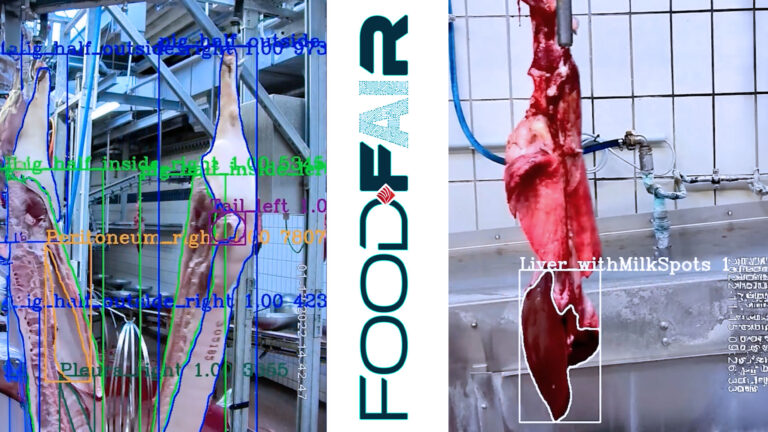

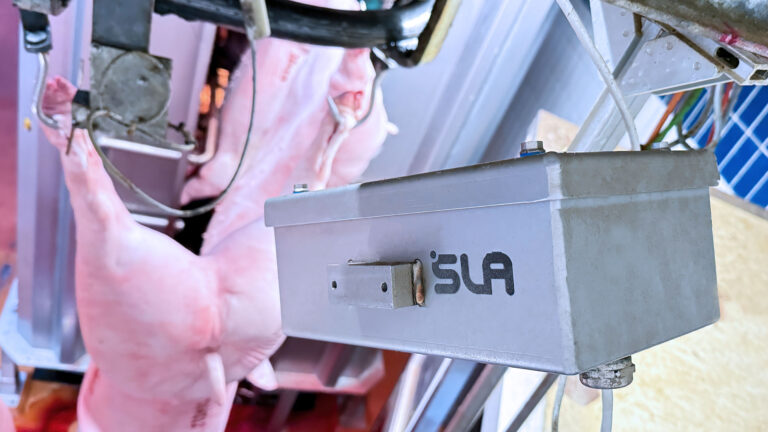

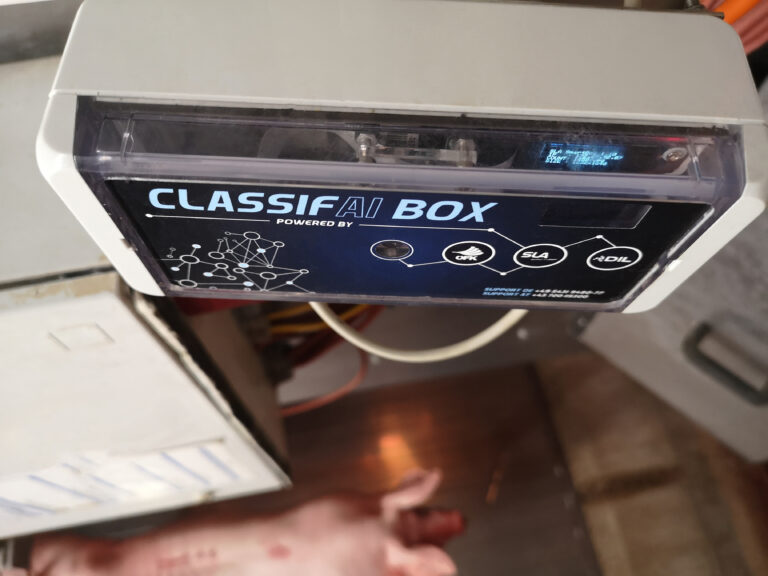

AI-supported slaughter number recognition

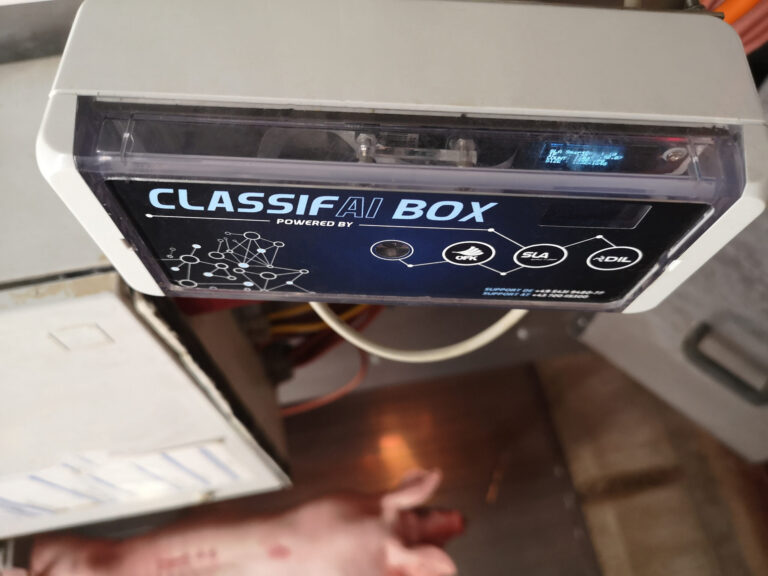

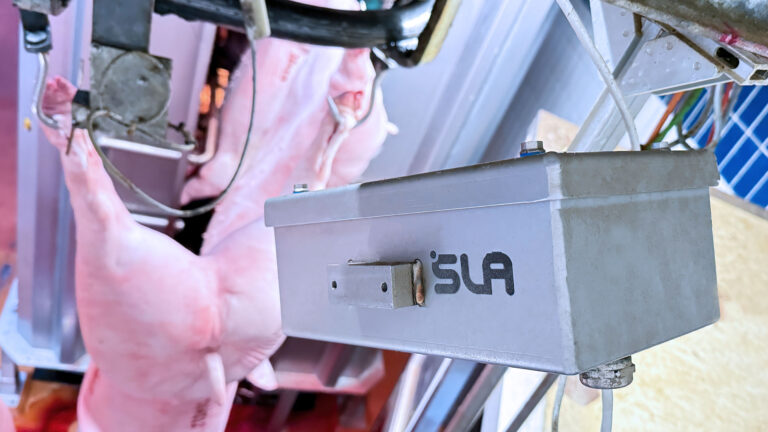

FOODFAIR's AI-supported carcass number recognition system automatically captures the number using high-resolution cameras, reads it using text recognition, and assigns it to the correct carcass in real time—even where manual entry would not be possible.

What the solution does

- Automatic reading of the slaughter number on the slaughter line

- AI-based text recognition with real-time assignment to carcasses

- Visual inspection possible if number is illegible (note for manual inspection)

- Interface for direct connection to ERP and QS systems

- Basis for further AI modules such as classification, assessment, or photo documentation

Your benefits

How automated number recognition is changing the production line

AI-supported slaughter number recognition stabilizes a previously error-prone step in the process. It ensures that animal data is reliably linked to production, even under difficult conditions. At the same time, it reduces the workload for staff and significantly improves traceability.

Error prevention

No more transposed digits or missing numbers due to manual entry.

Increase process reliability

Reliable link to classification, diagnosis, and animal welfare data.

Automation at critical points

Data capture even where manual entry would be technically impossible or too risky.

Increase in efficiency

Less rework, better data quality – and clear allocation in real time.

Cost-effective integration

Low installation costs, can also be implemented in existing or older systems.

Your possibilities – our goal

The basis for traceability and digital process chains

With automatic slaughter number recognition, you create a digital reference that can be used without any additional manual steps—for direct connection to other modules and for tracing each individual animal. The solution is particularly suitable for slaughterhouses that want to digitize processes without completely rebuilding their infrastructure.

With automatic slaughter number recognition, you create a digital reference that can be used without any additional manual steps—for direct connection to other modules and for tracing each individual animal. The solution is particularly suitable for slaughterhouses that want to digitize processes without completely rebuilding their infrastructure.

- Unique digital identification of carcasses

- Reduce manual entries in the production environment

- Seamlessly integrate additional AI modules such as classification or photo documentation

- Creating future-proof infrastructure even in older businesses

- Offering alternatives to RFID technology – with comparable quality

The next step starts here

Traceability begins with the number

With AI-based slaughter number recognition, you can automate a crucial point in the production process—and lay the foundation for all further digital steps toward transparency, animal welfare, and quality assurance.

Let's work together to find out what solutions your business really needs—today, tomorrow, and the day after tomorrow.

5 common questions about AI-based slaughter number recognition:

How does AI recognize the battle number?

A camera captures the number on the carcass. AI automatically reads it using text recognition.

What happens if the number is smudged?

The system issues a notification and allows for manual follow-up checks if necessary.

Can the solution be integrated into existing systems?

Yes – it can be connected to ERP, QA, or control systems.

How complicated is the installation?

The solution can also be implemented in existing systems with minimal effort

For which businesses is it suitable?

Especially for slaughterhouses with documentation requirements, traceability programs, or high throughput