Our AI solutions

Product recognition

Automatically recognize products – sort, assign, document.

Your Challenge Challenge Challenge

If sorting errors occur, quality suffers.

Whether in cutting, packaging, or labeling, the correct allocation of products is crucial for quality, traceability, and complaint prevention. However, manual identification is error-prone, dependent on personnel, and difficult to implement consistently when there is a high variety of items. At the same time, the requirements for digital documentation and auditability are increasing.

Our Solution Solution Solution

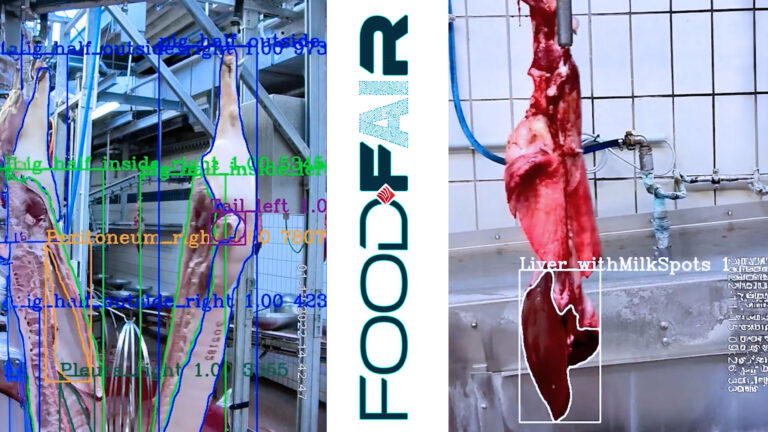

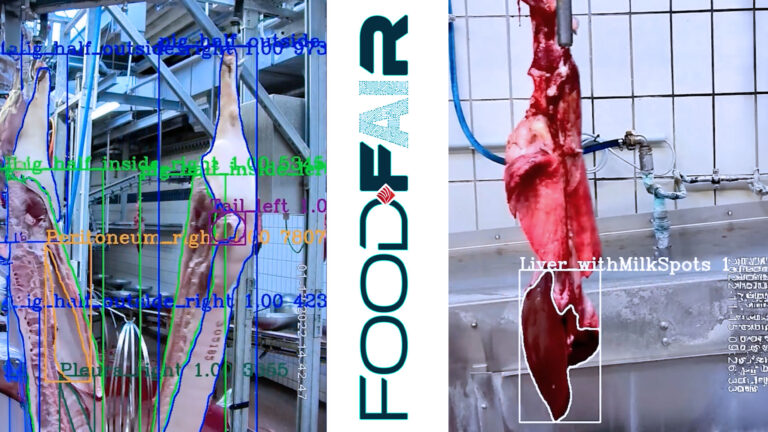

AI-supported product recognition

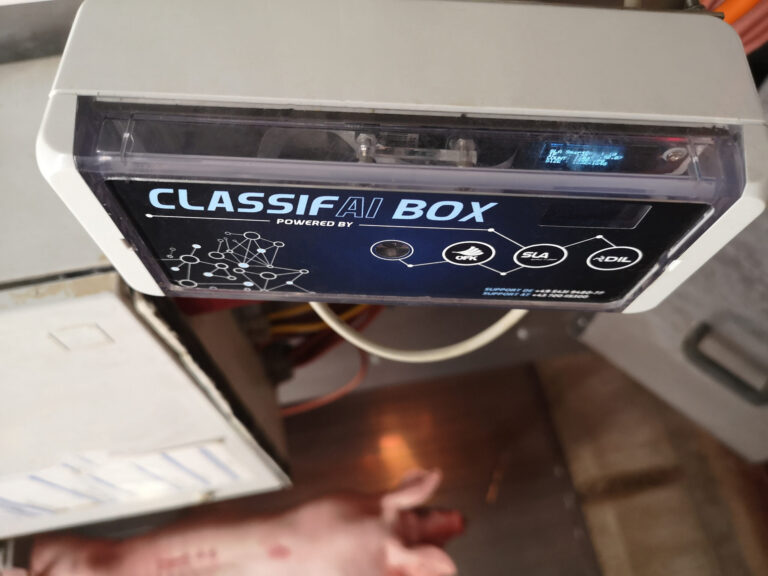

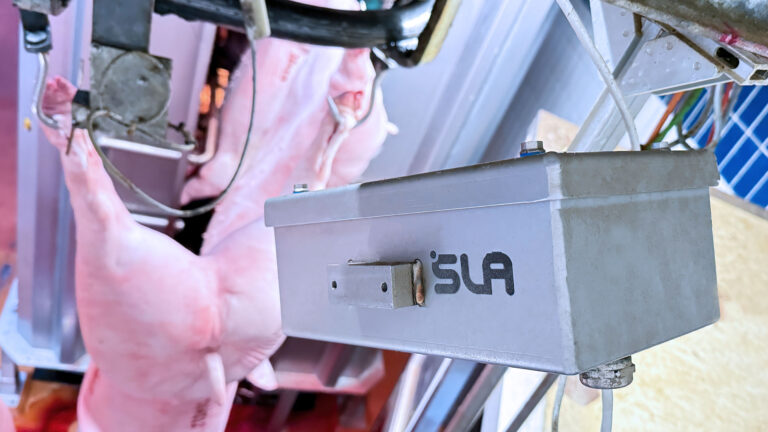

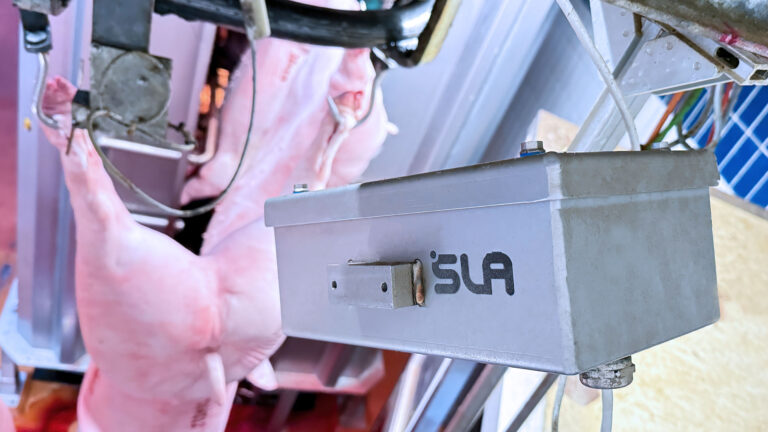

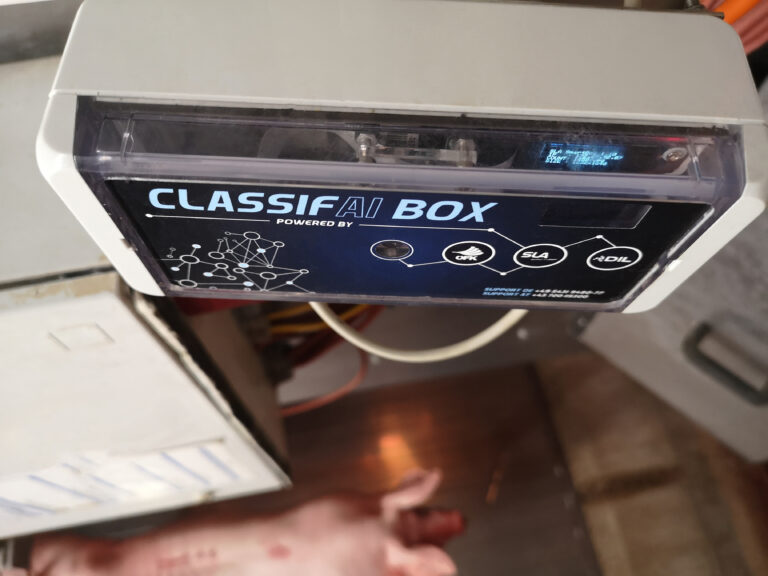

FOODFAIR's AI-based product recognition automatically identifies items at defined transfer points. It reliably assigns them to the correct product category – regardless of staff or their daily form. The system can be integrated into existing packaging and documentation processes, thereby supporting a continuous digital production flow.

What the solution does

- AI-supported product recognition based on camera images

- Reliable, automatic assignment to defined product categories

- Integration into existing sorting, packaging, or labeling systems

- Digital traceability through article code linking

- Suitable for use in businesses with a wide variety of products (e.g., meat, fruit, vegetables)

Your benefits

What AI offers – and how you can benefit

Automated product recognition prevents incorrect batching, reduces the workload for employees, and minimizes rework. At the same time, process stability increases—even with changing personnel or high cycle rates.

Reliable product identification in real time

Automatically recognizes and sorts items – without manual intervention.

Fewer incorrect batches and complaints

Sorting errors are systematically avoided – product quality increases.

Relief for staff

Less dependence on experience, shorter training periods.

Improve digital traceability

Article codes and classification are automatically documented.

Increase efficiency – mitigate skills shortages

AI replaces manual checks and ensures process reliability.

Your possibilities – our goal

Sort. Process. Trace—with AI at a whole new level.

Product recognition can be seamlessly integrated into existing lines. It is suitable for all food companies with sorting or packaging requirements and a wide variety of items. It brings measurable added value, particularly in the context of changing personnel, increasing traceability requirements, or quality assurance.

- Automated, image-based product allocation at item level

- Automated data transfer in packaging and documentation

- Process optimization through consistent batch formation

- Reduction in manual intervention – despite high variety

- Further development towards multi-module detection (damage, shape, color)

The next step starts here

When the process works, the strategy begins.

With FOODFAIR, sorting quality is not estimated – it is recognized. Our solution is connectable, practical, and future-oriented. Get advice now.

Let's work together to find out what solutions your business really needs—today, tomorrow, and the day after tomorrow.

5 common questions about product recognition with AI:

How exactly does product recognition work?

The product is photographed at defined transfer points. The AI recognizes it visually and automatically assigns it.

How will the result be used?

The corresponding article code is issued and flows into further processing – e.g., labeling, packaging, batch formation.

Which products can be detected?

Pieces of meat, fruit, vegetables, or other items—the system can be trained to recognize new product groups.

Is the solution only suitable for new systems?

No – it can be integrated into existing lines, e.g., as a supplement to packaging processes.

How much effort is involved in implementation?

Depending on the operating situation, implementation is possible with manageable effort—integration is open-system.