Our AI solutions

Photographic documentation

of carcass halves

Every animal documented – objectively, with images, and traceable.

Your Challenge Challenge Challenge

When evidence is lacking, trust becomes a matter of interpretation.

Whether it's cutting, contamination, or conspicuous features, many companies lack objective evidence when it comes to complaints. Carcasses are classified, but not visually documented. This not only complicates internal quality assurance, but also communication with customers, inspection bodies, and audits.

Our Solution Solution Solution

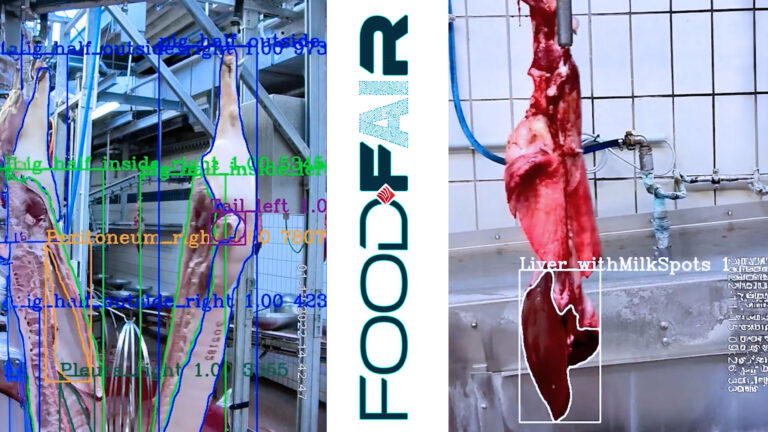

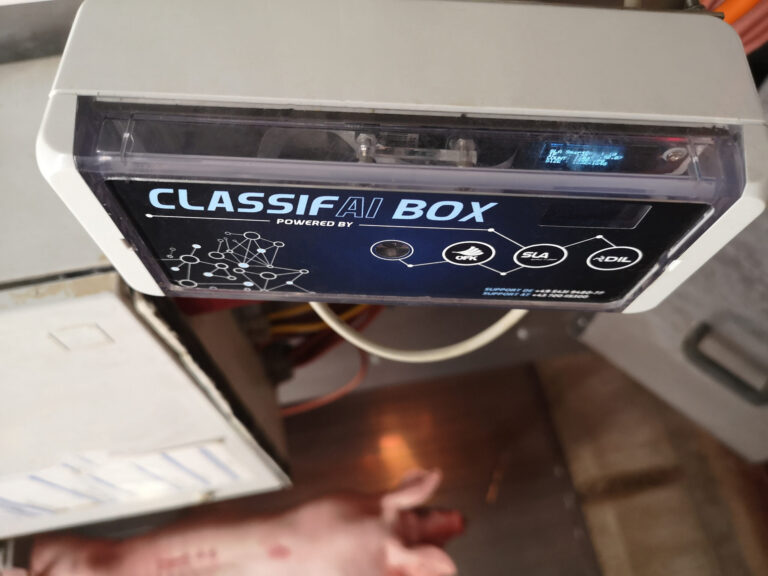

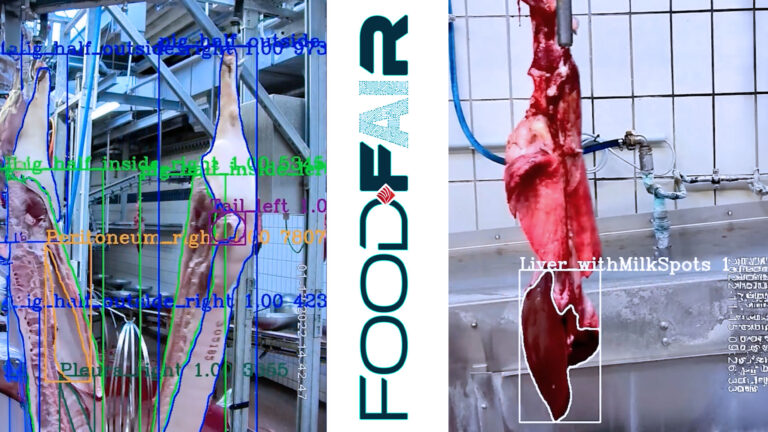

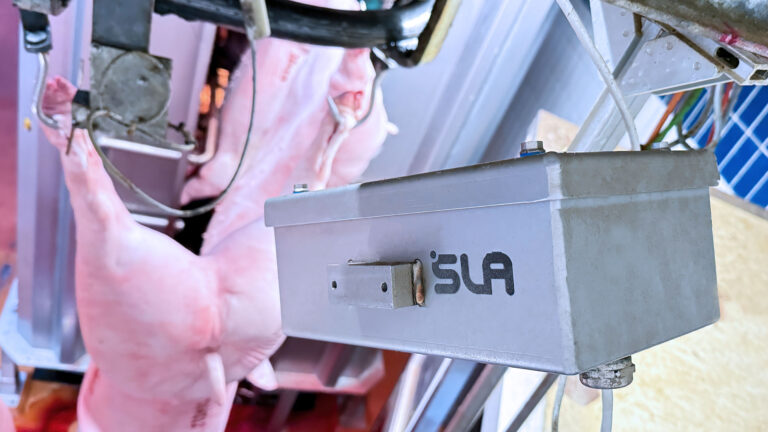

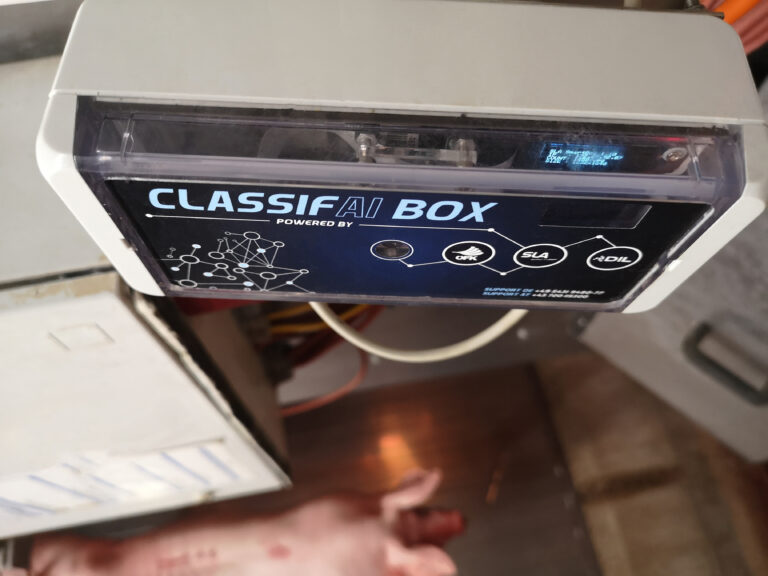

AI-supported photo documentation

With FOODFAIR's automated photo documentation, every carcass is captured visually – fully automatically, precisely timed, and linked to animal and classification data. The images are immediately available in the system and serve as an objective basis for queries, evidence documentation, or quality assessment.

What the solution does

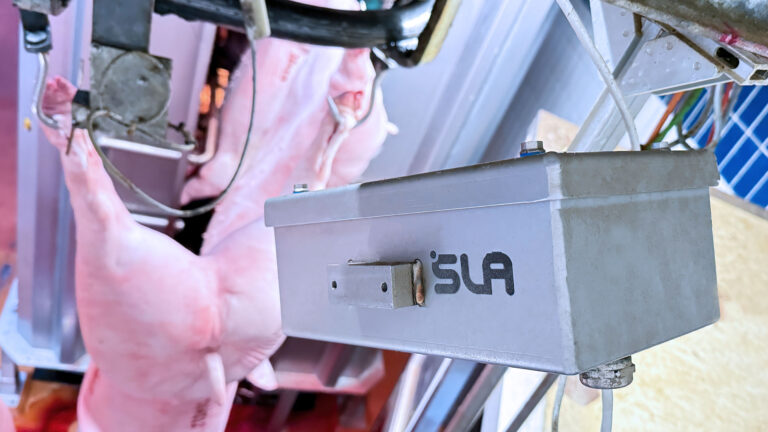

- Automated image capture of carcass halves in real time

- Triggered by sensor or AI – synchronized with the slaughter proces

- Link to animal, slaughter, and classification data

- mages available for quality assurance, customer portals, or traceability

- Suitable for cattle and pigs – also under export standards

Your benefits

How objective image documentation is changing everyday life

The AI solution reduces queries, simplifies checks, and builds trust—both internally and externally. Data is available centrally, enabling significantly more efficient complaint and QA management.

Your possibilities – our goal

Every carcass counts – and so does every piece of evidence

Die FOODFAIR-Lösung bringt Konstanz in einen Bereich, der bisher oft auf Sichtkontrolle und Einzelentscheidung beruhte. Sie ermöglicht lückenlose Dokumentation, digitale Rückverfolgung und gezielte Rückmeldungen an Lieferanten oder Kunden.

The photo documentation also serves as the basis for future AI evaluations—for example, for the automatic detection of anomalies, contamination, or cuts. Together with modules such as cattle classification or organ diagnosis, this creates a comprehensive QA system.

- Close visual gaps in quality assurance

- Save time in complaints, quality assurance, and customer communication

- Make data usable for long-term evaluation, training, or risk analysis

- Establish consistent processes for audits and certifications

- Laying the foundation for automated image analysis